* Reviews

*

"The message on the pen says it all. Thank you for being you, for being dedicated, sympathetic to my worries, for being brave and bold as a surgeon, and yet being impeccably gentle with your work. You helped me feel whole again. Indebted to you Sir. May God Bless you and your family from here to forever. With much respect and love."

-Sara

* "Honestly Dr. Yaremchuk has drastically changed my life forever. When I first came to him for my rhinoplasty consult I was on constantly the verge of tears about my appearance. I had a previous surgery from a different surgeon that had left me disfigured in my eyes. I went from having a small bump on the ridge of my nose to having my nose completely sideways post opt. I came to Dr. Yaremchuk in hopes that he could correct or even just partially correct my nose. Not only did he deliver, he exceeded all my expectations! He gave me back the nose I was born with (even a little cuter!) I HIGHLY recommend Dr. Yaremchuk and his staff to anyone looking for superior results. - Stephanie Poirier"

* "Everybody tells me that even after 2 years I have the best facelift they have ever seen. I know many of my friends and acquaintances have gone to see you. I hope some have actually gone ahead with the surgery. It makes such a difference in one's life."

* "I had an informal high school reunion recently, and though no one noticed the surgery, I felt some of my friends were, somehow, in "awe" of me. I felt they treated me better than before, and they respected me more. I felt like a real leader. I notice [second patient] is now more confidant, too. She has enjoyed shopping for new clothes to fit her new and improved physique. Her eyelid and nose look more natural and her chin more feminine. We thank you."

* "It's been a little over a month since my surgery and I'm just writing to say thank you very much for all the hard work you've done for me so many times already! I can only imagine how difficult it is trying to fix something that already turned into solid scarring instead of normal tissues after too many surgeries! I really don't know what would've happened to my face if I didn't find you!"

- This patient received revisional cosmetic surgery from Dr. Yaremchuk to correct deformities created during previous experiences with other plastic surgeons

* "I am so pleased with the results. The swelling has gone down alot. And I really look so good. And I know it will get even better with time. I still don't look exactly Iike I did before any surgery, but I did not expect that because of the previous operations. My forehead is still slightly higher than before. But I am very happy with what you could do. Thank you. The Lord has blessed you with a great skill to help people."

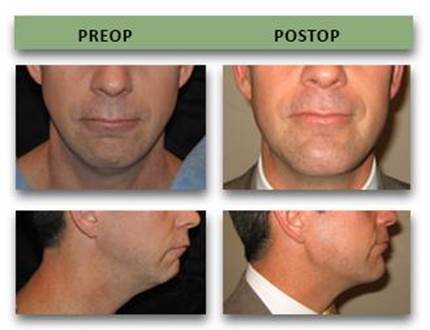

"It has been about a month since I stopped by for a Mandible Implant and my recovery has gone very well. The swelling and soreness went away weeks ago and I am back to exercising again. I'm really happy with the work you did and the great care of your staff."

- This patient underwent mandible implant surgery

* "I just wanted to thank you very, very much for the incredible results I already see from my surgery last week... The results look so natural. I'm so happy!"

* "I can say this with confidence: Dr. Yaremchuk saved my life. He saved the quality of my life... if you need plastic surgery, you can't do better than Dr. Michael J. Yaremchuk."

"...Watching you move confidently and even a bit excited toward a solution for my very challenged case, well it was almost [as] exciting for me too! Your talent and your attention to my case is something that warrants a note, a huge thanks, a big hug, applause and so much more.... My gratitude always."

"I just wanted to take this opportunity to tell you how thrilled I am with the results of my chin reduction surgery! Thrilled beyond measure. My only regret is not having found you years sooner. You are every bit as brilliant and talented as your reputation suggests."

"Thanks again for the great work, it's changed my life. I'll see you in a couple of years!"

* "I look better now then I ever did in my life even when I was in my twenties before I ruined my face.... I love the shape of my eyes, I couldn't wish for better, I look so pretty! You are and absolutely unique craftsmen doctor! I don't think there is anyone as talented as you are and it was nice to see that you are passing your experience to young surgeons, they are so lucky to learn from you! All the best to you from a very happy girl"

* "I will be forever grateful for everything you have done for me. You have changed my life!"

* "I know I'll have much more to thank you for as my recovery progresses - but I want to thank you now for doing my surgery and to tell you how much I appreciate your expertise and care. I felt I was in good hands and therefore was not too nervous. I'm grateful and very much appreciate your kindness in fixing my deviated septum along with my other nose imbalances. Your staff have been very helpful as well. Marge is incredibly pleasant to talk with by phone and the office staff and nurses have been very nice and quick to answer questions and concerns. Jan, who I consider "my" nurse, is sweet, efficient and attentive. Mary was great too as was the anesthesiologist who smoothly kept me in 'la la land' while you worked your magic."

- This patient underwent rhinoplasty surgery

* "I'm absolutely delighted with the outcome. Not just because the changes have made a vast improvement to my looks, but that not a single person has ever questioned me regarding PS. I could never have imagined my look could change so much, yet so discreetly. Fantastic.

I can't believe how great my eyes feel. I always thought I had allergies and that was why they hurt and burned so much. I am thrilled! The best part is not only do they feel great they look great too! Thank you Dr, Yaremchuk. The whole experience was wonderful. You have a great staff as well. As for the lip injection I would appreciate your discerning eye. If you feel i shouldn't

trust your judgement as i did when you recommended not doing the ULB. You are truly an artist."

* "It is as much a blessing as a relief to have you as my surgeon. Your peerless skill is matched only by your immense kindness and compassion. Thank you or all you do for me and for countless others. You have clearly devoted your entire life to our care, and we are all the better for it."

* "I have been meaning to write to you to tell you again how happy I have been with the brilliant work you did on my chin and jaw. I have been utterly thrilled ever since I was able to see the final results... You really are a genius. The combination of being an artist and a doctor is quite an impressive gift..."

-This patient underwent cosmetic surgery of the chin and jaw

"... I'm looking way better and I'm really happy and grateful for all amazing work you did for me!... you are an amazing artist and I trust you with my face and my life. Lots of love, and my best wishes to you and your fantastic team!"

"I just want to thank you so much for what you have done for me. You really are the best in your field."

* "There really is no way for me to adequately explain the feeling of incredible gratitude I have for your help last week... I shall always remember the compassionate assistance you showed me."

* "I, unfortunately, have had a couple awful encounters with plastic surgery. Borderline disasters. Dr. Y has tactics in solving problems that other doctors don't. I had an under the eye problem and the only solution I thought there was was cheek implants. Instead with his orbital rim implant he fixed the problem perfectly. I had been self conscious about my looks my entire life and now I am no longer... He was kind to me and to my father and his staff are sweet people as well... [H]e's just a good guy who happens to be the best at what he does. I'm beyond sastified and will never have to experience a painful cosmetic operation again thanks to him. My life is changed."

-This patient received revisional cosmetic surgery

* "I know you said I'd get the final results in about 3 months, but I'm already ecstatic at the results. My only regret is that I didn't do this 5 years ago."

* "In terms of surgical skill and experience, Dr. Yaremchuk is pretty much as good as it gets. I can happily put my full weight behind this review to say that I unequivocally recommend him to anyone looking for facial skeletal changes.

You can also review his literature contributions online and see that he is the leader in the field. In fact, I doubt anyone out there even comes close.

Beyond the surgical elements, his response times, willingness to engage, empathy, and overall bedside manner are great. True intent always shines through, and you can see that he really is in it for the patients - i.e., he's passionate about putting his patients first and taking on difficult cases to get people the result they're looking for

"

* "It's unbelievable that a just a few millimeters along the mandible could make such a huge difference -- but they have. I don't even think about the implants anymore, they are just a part of my native face. I feel like this is how I was supposed to look, the best version of me. My only regret is that I didn't do this earlier. "

CT Designed (Bespoke) Facial Implants

Dr. Yaremchuk has innovated the use of custom facial implants for both aesthetic and reconstructive indications. Precise measurements obtained from CT scans allow creation of virtual and physical models that allow Dr. Yaremchuk to design implants unique for the patient.

The three-dimensional image reveals the exact underlying skeletal anatomy of the patient. Since one's facial skeleton is the fundamental determinant of their appearance, it can be invaluable to patient understanding during the consultation. The 3D CT makes surgical planning more precise when using both custom and off-the-shelf implants.

These Computer Aided Designed (CAD) and Computer Aided Manufactured (CAM) or CAD/CAM implants are especially useful for the following patients:

- Patients who desire the best possible aesthetic result made possible by unlimited design options and perfect implant fit

- Patients with significant asymmetries

- Patients who are unhappy with prior skeletal reduction and desire skeletal restoration

- Patients who after orthognathic surgery are left with noticeable contour irregularities

Best Possible Aesthetic Result

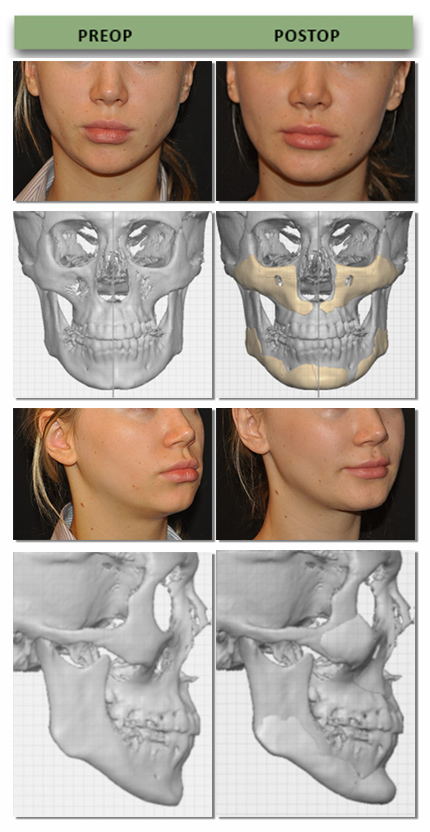

Below are planning images derived from a CT following a patient consultation. In this case, the patient desired to correct the asymmetry in her lower jaw, as well as create a more defined chin and more prominent cheek bones. Bespoke facial implants were designed to provide these skeletal changes, which would be reflected in the contours of her face.

The below image on the left shows the patient's underlying skeleton. The image on the right shows the custom-made bespoke implants overlying her skeleton.

* Below is transition showing the impact of the skeletal alteration on her appearance.

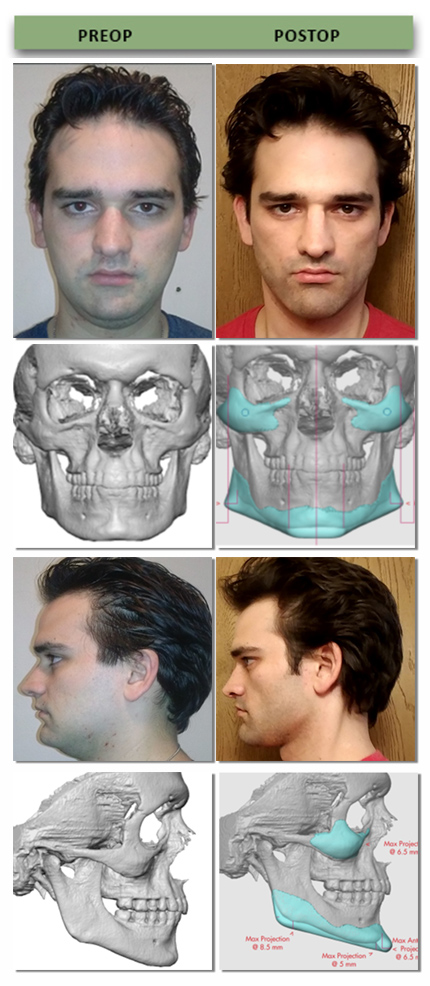

This patient had custom implants placed to augment his deficient chin and mandible.

This transition showing the impact of the skeletal alteration on his appearance.

Significant asymmetry

This patient with hemifacial microsomia had been treated with sagittal split osteotomy, horizontal chin osteotomy and later distraction osteogenesis in attempts to reconstruct a symmetric mandible. CAD/CAM implants brought symmetry and balance to her face.

Skeletal Restoration

Some patients are unhappy with prior skeletal reduction and desire skeletal restoration

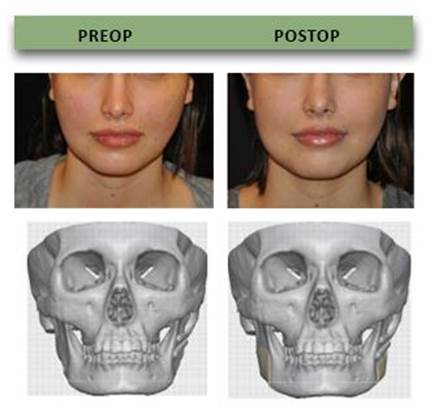

* This patient had undergone mandible angle reduction in the past. She disliked the new look and desired restoration of her angles.

* Custom implants were designed to restore angles which provided the desired lower face width.

After orthognathic surgery

The patient below had undergone LeFort maxillary advancement and sagittal split osteotomy of the mandible. The upper midface, mandible and chin were augmented with CAD/CAM implants to restore facial balance and correct border irregularities.

Patient Examples

*This man underwent CAD/CAM implant augmentation of midface and lower jaw as well as rhinoplasty.